Cummins Engines: Key Maintenance Practices

Cummins engines are renowned for their durability and power, commonly found in trucks like the Ram 2500 and 3500. However, to maintain optimal performance, owners should keep the following tips in mind:

1. Regular Oil Changes

- Importance: Using high-quality diesel engine oil and changing it regularly (typically every 7,500 to 15,000 miles) helps protect critical engine components.

- Tip: Always use filters that meet Cummins specifications to ensure proper filtration and performance.

2. Fuel Quality

- Importance: Diesel fuel quality directly affects engine performance. Contaminated fuel can lead to serious issues.

- Tip: Use clean, high-grade diesel from reputable sources and consider adding fuel additives to reduce injector deposits.

3. Coolant System Maintenance

- Importance: Maintaining the proper coolant level and using the recommended coolant type is essential to prevent overheating.

- Tip: Check the cooling system regularly and flush it as needed, typically every 2 years or 30,000 miles.

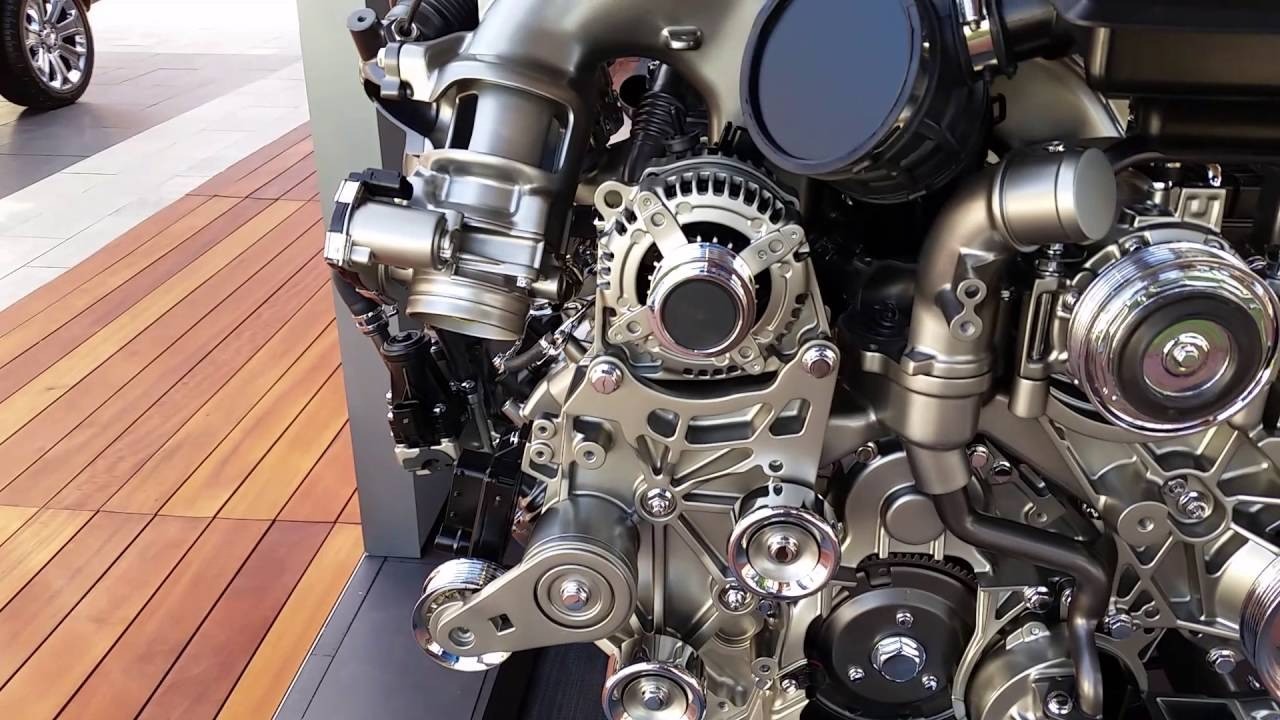

Duramax Engines: Care and Attention

Duramax engines, featured in models like the Chevrolet Silverado 2500HD and GMC Sierra 2500HD, are designed for efficiency and performance. Here are some maintenance tips specifically for Duramax engines:

1. Change Engine and Fuel Filters

- Importance: Dirty filters can restrict fuel flow and affect engine performance. Changing the engine oil filter and fuel filter regularly is vital.

- Tip: Replace the fuel filter approximately every 10,000 miles or according to your owner’s manual.

2. Monitor EGR System

- Importance: The Exhaust Gas Recirculation (EGR) system reduces emissions but can accumulate carbon buildup over time.

- Tip: Regularly inspect and clean the EGR valve and cooler to avoid performance issues.

3. Check Transmission Fluid

- Importance: Many Duramax engines are paired with Allison transmissions, which require proper fluid levels and condition for optimal shifting.

- Tip: Change the transmission fluid according to the manufacturer’s recommendations, usually around every 50,000 miles for heavy-duty use.

HEMI Engines: Keeping Performance High

HEMI engines, known for their power and versatility, can be found in vehicles like the Dodge Ram 1500 and Charger/Challenger. To keep these V8 engines running smoothly, consider these maintenance strategies:

1. Routine Spark Plug Inspections

- Importance: Spark plugs play a crucial role in engine performance. Worn or fouled plugs can lead to misfires and decreased fuel efficiency.

- Tip: Inspect and replace spark plugs every 30,000 to 100,000 miles, depending on the specific type used.

2. Maintain the Air Filter

- Importance: A clean air filter ensures optimal airflow to the engine, enhancing combustion and overall performance.

- Tip: Check the air filter every 15,000 miles and replace it if it's dirty or clogged.

3. Regular Brake Checks

- Importance: Although not directly related to the engine, ensuring your brake system is functioning properly is crucial for safety and performance, especially in high-powered vehicles.

- Tip: Inspect brake pads, rotors, and fluid levels regularly—ideally every 10,000 miles.

Conclusion

Caring for your Cummins, Duramax, or HEMI engine goes beyond just regular oil changes; it involves attentive maintenance practices tailored to each engine's unique characteristics. By following these guidelines, you can help ensure that your vehicle remains reliable, efficient, and ready to tackle any challenge on the road.

For all your automotive parts needs, whether you're looking for replacement filters, fluids, or other essential components for Cummins, Duramax, or HEMI engines, browse our selection today. Investing in quality parts is just as important as maintaining your engine!